THE G R E E N E S T MANUFACTURING COMPANY IN THE NETHERLANDS

from bio-based residues to renewable, natural raw materials

STERCORE has an innovative approach in which innovative, technical and sustainable processes are used to achieve CO2 reduction by producing high-quality organic fertilisers and green energy from renewable residues in order to balance ecology, economy and society

.

STERCORE produces sustainable ENERGY

and Bio-Based Carbon

...and we make it from the most renewable organic resources

available worldwide.

The source that we do this with is also known worldwide to be

an environmental pollutant.

But without it, we cannot feed you, your children or the world.

Our source is: animal MANURE!

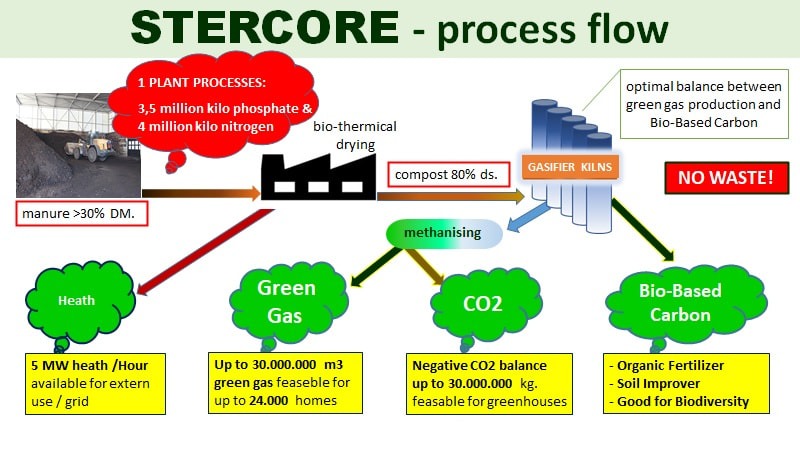

We convert this manure into Bio-Based Carbon and green gas.

We deliver the green gas to the local gas grid.

The Bio-Based Carbon is specially developed as an organic fertiliser and soil improver to reduce the use of chemical fertilisers.

Bio-Based Carbon is produced in an environmentally friendly way, the process causes no waste. Bio-Based Carbon is easy and safe to use and

Bio-Based Carbon promotes biodiversity in the soil.

Video impression of the factory we will build in Emmen

Nitrogen?

The entire STERCORE process is electrified and, where possible, measures are taken to reduce nitrogen emissions. The plant can convert approximately 350,000 tonnes of solid manure a year into Bio-Based Carbon and green gas, reusing all the captured nitrogen. The nitrogen emission is only 57 kilos per year, the equivalent of the nitrogen emission of only 16 people! We do not cause any N deposition on a Natura 2000 area.

CO2?

STERCORE is fully committed to the latest RED+ legislation and regulations. To this end, a strategic value creation, sustainable development goals benchmark (SDG) and a Green House Gas (GHG) & Life Cycle Assessment (LCA) study were carried out.

Short summary: Depending on the calculation method, the CO2-eq. avoided by one STERCORE plant amounts to approximately -225,000 to -345,000 tonnes of CO2 annually.

The total CO2 emissions in Drenthe in 2020 amount to 3,254,600 tonnes: the CO2 avoided by STERCORE for Drenthe can therefore easily amount to approx. 10%!

Sustainable energy?

1 MW of energy corresponds to approximately 113 M3 of green gas. With an annual production of approximately 23 million M3 of green gas by STERCORE, this equals approximately 739 TJ of renewable energy.

This corresponds to about 15% of the total renewable energy produced by means of sun, wind and biomass in Drenthe in 2020. Solar power in Drenthe, with now hundreds of hectares of solar meadows at the expense of fertile agricultural land, produced a total of 1,600 TJ in 2020. STERCORE will produce the 739 TJ on only 2.2 hectares!

STERCORE's main activity is to produce sustainable, high-quality end products from renewable raw materials such as animal manure and digestate from co-fermentation. These end products include Bio-Based Carbon - a high-quality, organic fertiliser and soil improver as a substitute for artificial fertiliser - and our 2nd main product, green gas.

The system

The STERCORE system has been specifically developed for the high-quality and sustainable processing of various types of biomass. The entire system is robust and operational 24/7. The basis of the process consists of tried and tested techniques, with innovations. The industrial air treatment system with bio bed and the fully pressurised building guarantee a low-emission and completely odour-free environment.

Sustainable process

This is an energy positive process that is fully electrified. The gasification process takes place under oxygen-free and almost atmospheric conditions. It concerns a modular scalable system. During the process, syngas is created which, through an innovative methanisation process (co-developed by DNV), is converted into "green gas" and can be fed directly into the local natural gas network. With a few technical adjustments, the system can also be used to produce Bio-LNG - and eventually hydrogen.

Residual streams

No waste is produced during the process and the water present evaporates completely. Nutrients such as ammonia and sulphur are recovered in the process and returned to value in the final Bio-Based Carbon product. The remaining CO2 is liquefied and delivered to greenhouse horticulture. The remaining system heat can be linked to an external heat demand.

No waste flows are created during the STERCORE process.

Video impression: a virtual visit of the factory

Partners of STERCORE